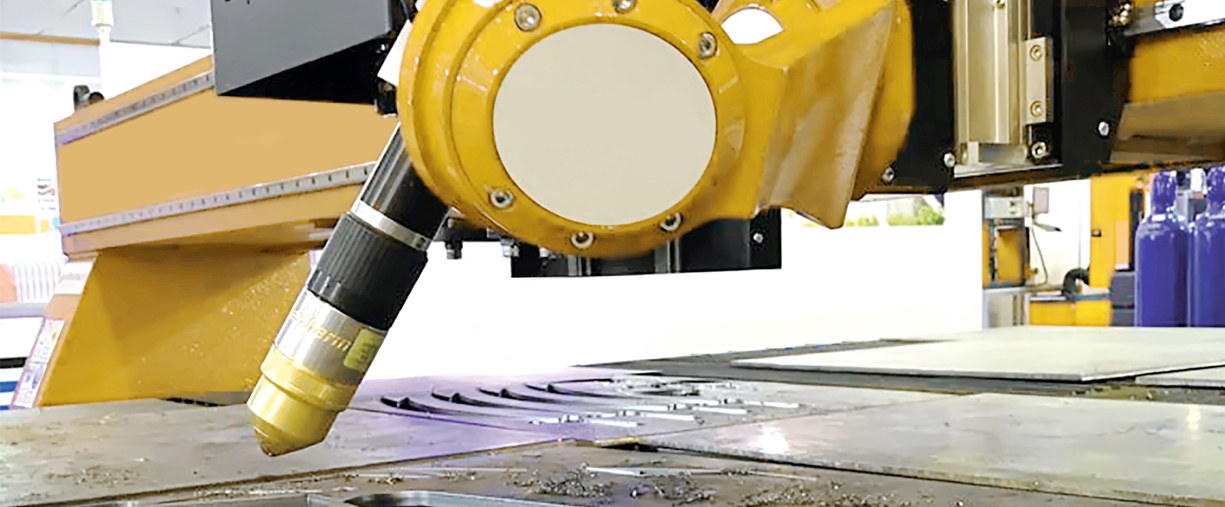

Bevel Plasma Cutting Machine

3D PLASMA BEVEL CUTTING HEAD SYSTEM

Cutting head can implement progressive and continuous cutting at X, Y, Z, ROTATE and TILT axes. Cuts can reach to 50 mm thickness on

black iron sheet at 450 + 20 by means of Hypertherm HPR400XD plazma cutting system. Axes are driven with Harmonic Drive motors,

patented product of Harmonic Drive AG.

On both axes Harmonic Drive i:50 transmission rated drive motors are employed. Height Control is being implemented with Arc Voltage

surveillance, and sensitive screwed axle is being performed via linear skid including module and sensors.

Module speed can reach till 10.000 mm/min. Magnetic separation plates and proximity sensors are employed for collision control. Thus,

damaging torch due to collision during operation is prevented. Sending cutting head to 0 point on both axes is maintained electronically by

means of a single button. As our Harmonic Drive motors are installed into the specially designed sleeve body, full protection against

damaging is maintained. Continuous inclined cutting process is being maintained via Pronest and Hypertherm control software.

True Hole technology, supplied by Hypertherm, is increasing the quality on bevel product. Sensitive cutting can be maintained with

minimum loss by means of fine resetting of the part via laser diode, installed onto the Bevel cutting head.

GENERAL FEATURES

• Positioning Speed 10.000 mm/min

• Lift Positioning Speed 30.000 mm/min

• Tilt X Positioning 30.000 mm/min

• Tilt Y Torch Positioning Angle ±45§+2§

• Torch Lift Stroke 300 mm

• Height Control Sensitivity 2 min. angle

ADVANTAGES

• Ability to cut at 5 axes continuously

• Inclined cutting of parts with complicated geometry

• Time e¨ectiveness during welded installation works

• Performance of both cutting and welding grooving

processes in single operation

MEASURE

| APL-B SERİSİ | Width(mm) | Length(mm | Height(mm) | Cutting Width(mm) | Cutting Length(mm) | Weight(KGS) |

| APL-B 15/30 | 2650 | 4400 | 2150 | 1650 | 3150 | 3650 |

| APL-B 20/40 | 3150 | 5400 | 2150 | 2150 | 4200 | 4800 |

| APL-B 20/60 | 3150 | 7400 | 2150 | 2150 | 6300 | 5950 |

| APL-B 30/60 | 4150 | 7400 | 2150 | 3150 | 6300 | 7400 |

| APL-B 30/80 | 4150 | 9400 | 2150 | 3150 | 8400 | 9200 |

| APL-B 30/120 | 4150 | 13400 | 2150 | 3150 | 12600 | 12600 |

| APL-B 30/160 | 4150 | 17400 | 2150 | 3150 | 16800 | 16100 |

| APL-B 30/200 | 4150 | 21400 | 2150 | 3150 | 21000 | 19500 |

| APL-B 40/60 | 5150 | 7400 | 2150 | 4150 | 6300 | 8900 |

| APL-B 40/80 | 5150 | 9400 | 2150 | 4150 | 8400 | 11100 |

| APL-B 40/120 | 5150 | 13400 | 2150 | 4150 | 12600 | 15400 |

| APL-B 40/160 | 5150 | 17400 | 2150 | 4150 | 16800 | 19700 |

| APL-B 40/200 | 5150 | 21400 | 2150 | 4150 | 21000 | 24000 |